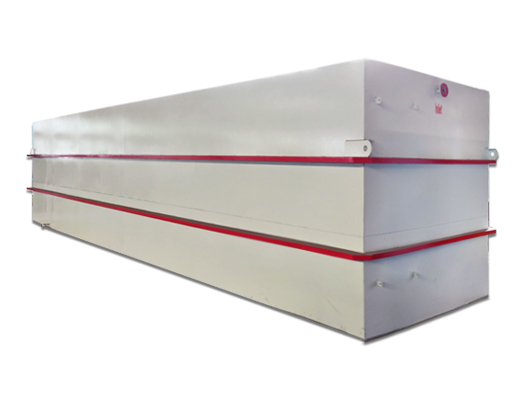

Hospital Sewage Treatment Plant

The hospital sewage treatment equipment adopts biological treatment technology, on the basis of summarizing the operation experience of domestic wastewater treatment devices at home and abroad, combined with its own scientific research achievements and engineering practice, it is designed to remove BOD5, COD and NH3-N, which has the advantages of stable and reliable technical performance, good treatment effect, low investment, automatic operation, convenient maintenance and operation, no area occupied by surface area, no need to build a house, no need for heating and insulation, etc. Based on the A/O process, the main body of the equipment is buried in the ground, reducing the floor space, and the economy is all set up underground, which is economical in operation, strong in impact concentration ability, high in processing efficiency, and convenient in management and maintenance.

Hospital sewage contains some special pollutants, such as drugs, disinfectants, diagnostic agents, detergents, as well as COD, BOD5, ammonia nitrogen, SS, pathogenic microorganisms, parasite eggs and various viruses, such as roundworm eggs, hepatitis virus, tuberculosis bacteria and dysentery bacteria. Compared with industrial wastewater and domestic sewage, it has the characteristics of small water volume and strong pollution power. If left unchecked, it will inevitably pollute water sources and spread diseases.

1. The secondary biological contact oxidation treatment process adopts push-flow biological contact oxidation, and its treatment effect is better than that of the fully mixed or two-stage series fully mixed biological contact oxidation pool. It is smaller than the activated sludge tank, has strong adaptability to water quality, good impact load resistance, stable effluent water quality, and will not produce sludge expansion. The pool adopts a new type of elastic three-dimensional filler, which has a large specific surface area, microorganisms are easy to hang the film, and the film is removed, and the removal rate of organic matter is high under the same organic matter loading conditions, which can improve the solubility of oxygen in the air in water.

2. The biochemical tank adopts biological contact oxidation method, the volume load of its filler is relatively low, the microorganisms are in the self-oxidation stage, the sludge production is small, and it only takes more than three months (90 days) to discharge the mud once (sucked or dehydrated into mud cake by manure truck and transported).

3. In addition to conventional high-altitude exhaust, the deodorization method of the buried integrated medical sewage treatment equipment is equipped with soil deodorization measures.

4. The whole equipment processing system is equipped with a fully automatic electrical control system and an equipment fault alarm system, which is safe and reliable in operation, and generally does not need special personnel to manage it at ordinary times, but only needs to maintain and maintain the equipment in a timely manner.

| Previous:Industrial Wastewater Treatment | Next:Residential Sewage Treatment Plant |

TEL

TEL

HOME

HOME