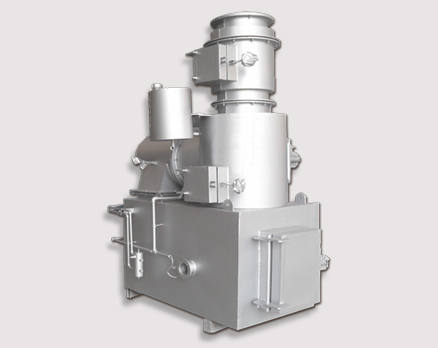

Industrial Waste Incinerator

1. Incineration method: This series of waste incinerators adopts the incineration method of primary pyrolysis and gasification + surround wind mixed combustion + secondary incineration + burnout treatment.

2. Product features:

1, well-designed, small area, can use simple canopy, can also build equipment room.

2. Simple operation, convenient maintenance, and operation mode: continuous operation.

3, save energy, safe and reliable, automatic ignition. Using the diesel fuel for combustion.

4. Low price and long operating life.

5, waste gas treatment method: high temperature + high temperature jet vortex combustion + secondary combustion + cyclone dust collector + chimney.

6. Incineration temperature: primary combustion chamber: 600-900℃ (adjustable temperature control); secondary combustion chamber: 900-1200℃ (adjustable temperature control).

7, furnace internal pressure: using negative pressure design, not backfire.

3. Safety indicators:

1. Before stopping the operation, the device has detected the cooling procedure of the combustion chamber, so that when the temperature of the combustion chamber drops to the set temperature, the incinerator will stop all operation.

2. There is a connection protection device between the control cabinet and the control equipment to avoid leakage. When the relative humidity is 85%, the insulation resistance of the electrical circuit is not less than 24 MΩ, and the leakage power supply is transmitted by the ground line. Metal hose is protected outside the line.

3. The equipment is verified by the technical department, and the oil road and gas road are installed firmly, and after the pressure test, there is no leakage phenomenon.

4. The composition of the incineration unit includes:

The primary combustion chamber, secondary combustion chamber, cyclone dust collector, chimney, flue, pipeline system, high pressure blower, secondary pressure induced draft fan, primary burner, secondary burner, and, electric control cabinet, temperature display device, detection device, etc.

5. Combustion process flow and brief description:

The waste is manually put into the primary combustion chamber of the furnace body, starting with automatic temperature control. According to the principle of three T (temperature, time and eddy current), the waste is fully oxidized, pyrolysis and burned in the combustion chamber of the furnace body. The flue gas produced by incineration enters the secondary combustion chamber, and the burned harmful substances in the flue gas are further destroyed in the secondary combustion chamber. In order to decompose the unburned substances and meet the emission requirements, the secondary combustion chamber is equipped with a combustion burner, and a unique secondary air supply device is configured to ensure the full contact of the flue gas with the oxygen at high temperature, and ensure the retention time of the flue gas in the secondary combustion chamber and adjust the air supply volume according to the oxygen content of the outlet flue gas in the secondary combustion chamber. Two combustion indoor temperature control and through the dust collector remove particles larger dust, make its incineration efficiency and damage removal rate above 99%, to achieve no odor, no stench, smokeless effect, achieve emission standards, and then into the chimney emissions into the atmosphere, the burning ashes by artificial extraction, screening, transfer and buried.

Six, the advantages of the furnace description:

Design life: the incinerator can meet the needs of all-weather operation, can run continuously and intermittently, the annual operation time is not less than 8000 hours, and the design life is more than 10 years.

The main shell of the furnace is steel structure, the inner wall is refractory casting material of different properties, the inner layer is high temperature resistant casting material, can withstand 1790℃, the middle is lightweight refractory material, not only can ensure the internal combustion temperature, but also keep the shell low temperature, to prevent scald, refractory material as the whole casting, not easy to fall off, not easy to corrosion.

Vii. Application Scope:

1, industrial waste (polymer waste): plastic PE, PU, rubber (tire), Paul, dragon, bao, bottle, fiber, foam, cloth, resin, acrylic, leather, sawdust, laminate, electric wood, urea powder, urea powder, cabbage, tape, paint, polymer, etc.

2. Medical waste: needle tube, gloves, wrap, gauze, blood transfusion tube, organs and other infectious waste.

3, general garbage: cardboard, paper scraps, wood chips, leaves and so on.

4, special waste: waste oil, waste solvent, sludge, dust collection pool, iron paint, mold filter screen residue, etc.

The design of the primary combustion chamber of the incinerator is due to the gasification incineration technology, the temperature in the incinerator moves from 200℃ to 400℃, and the incineration process will not produce dissolved block, slag block, sintering and other problems in the garbage.

The secondary incineration burner and the annular air supply device are provided in the secondary mixed incineration room.At high temperature, the combustible gas in the flue gas can be fully burned, and the gas produced by the gasifier can be fully mixed and burned to prevent the escape and late burning of the carbon matter in the gas flame. Flue gas into the high temperature combustion chamber due to the tangential into and combustion air cut combustion way, make the flue gas in the combustion chamber can be fully burned again at the same time using the rotating air for flue gas dust removal, burning flue gas in the furnace stay time more than 2 seconds, make the flue gas and combustible gas in fly ash combustible completely burned.

In the upper part of the incinerator, there is a dry exhaust gas purification equipment, which adsorbs the hydrogen chloride and sulfur oxide produced in the incineration, and the odor and other components in the flue gas are decomposed at high temperature. The flue gas purification system is equipped with the neutralization reaction of calcium hydrogenated filter brick and acid gas, to achieve the purpose of absorbing acid gas and purifying tail gas, and reduce the harmful components in the flue gas to the hazardous waste incineration pollution control standard (GB18484-2001) " and other standards.

| Previous:Muncipal Waste Incinerator | Next:Medical Waste Incinerator |

TEL

TEL

HOME

HOME